Proteco srl is an Italian company specializing in the construction of machines for the production of CTC cables. The majority of its activity is directed, since the very beginning, to R&D, to enhance the process technology and create new products.

In the CTC field, one of the priorities, when it comes to product evolution, is to produce transposed cables with enamelled strips thinner and thinner; this in order to reduce the Foucault currents, which are detrimental as orthogonal to the main current flow. Of course, a reduced thickness of the strips requires a higher amount of them to get the same total cross section area for the current flow.

A

higher number of strips leads in turn to a reduction of the

transposition pitch, in order to maintain the possibility to easily

wind the cable in the transformer.

Proteco’s efforts in this

direction have already brought, a few years ago, to the creation of a

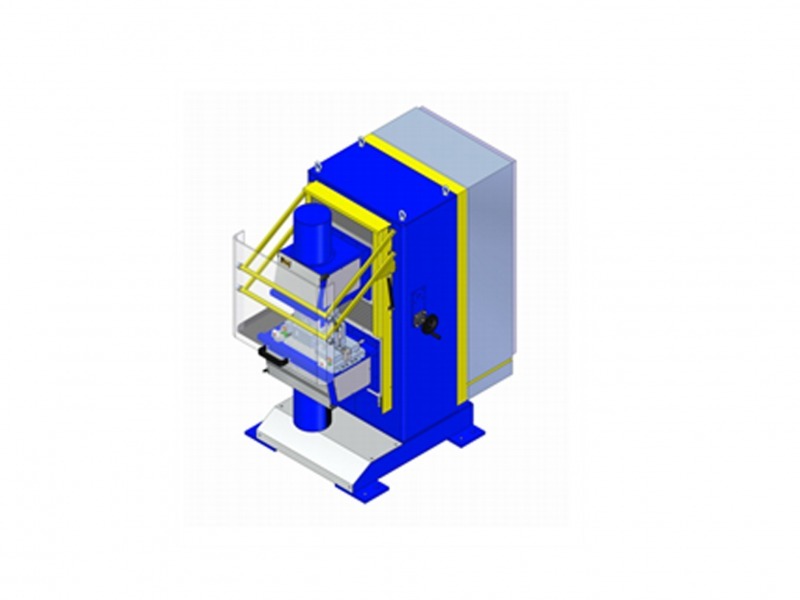

new CTC machine with innovative features, thanks to a rotary

transposing device. This machine, known as TH5.E in its current

release, has heavily enhanced the ergonomy standard and the

production quality of the transposed cable.

The new invention,

now being patented, goes beyond this, introducing and additional

motion in the machine, that creates a synchronous

folding of the enameled strips during the transposing process.

The

machine is called TH Synchro, a name given by this new operating

principle, and completes the productive range of the "bigger

sister". This machine is equipped with 4 servo-motors, thus much

more sophisticated in terms of control.

This new invention from Proteco faces and solves the production's problems arising from very small strips. The machine allows to bend any kind of soft or hard copper strips as thin as 0.7 mm and to get a transposing pitch as short as 16 mm.