The lines for the production of CTC manufactured by Proteco are characterized by some very special features:

• original operating principle for the transposition that offers better quality and higher speed

• easy setting of the line, totally assisted by servo motors and fully electronic control

• max attention to the ergonomy and the safety

• energy saving by correct and accurate sizing of the motors

• UPS supporting the basic functions in case of blackout

• sophisticated electromagnetic braking system for taping machines

• possibility of expanding the production to the evoluted ventilated continuously transposed cables – VCTC

The Stranding Cage is a modular structure made of disks connected through a central tube. Each disk holds the bobbins through pneumatic spindles on cradles shaped as open forks. The rotating structure is supported by idle wheels.

The forks are convergent to the center line to minimize the angular deviation of the strips.

The strips are tensioned by a block brake. The braking force is limited to a minimum, just enough to avoid the unrolling while stopping the line. This prevents from jerks that can deform the strips.

Each strip is guided inside tubes, that makes easier the threading of the machine.

The cage is rotated by an high torque electric motor with gear reducer, by using a very original configuration.

The emergency stop and the retention of the cage while loading are made by multiple pneumatic brakes.

Main data

Number of bobbins per disk: 8, 10, 12

Bobbin flange dimension: 500, 560, 630 mm

Bobbin weight: 270 up to 400 kg

This machine brakes the strips and conveys them from the stranding cage to the transposer. It rotates synchronized with the cage.

The strips are back-twisted and converged to the center line passing through tubular guides.

A dosing pump, with drip tray for excess, drops oil on the strips giving them the requested lubrication.

In few words this machine can apply a back-tension, clean and lubricate the strips at once.

The machine is equipped in the standard configuration with a single or double pay-off for the tape interposed between the stacks of continuously transposed cables – CTC.

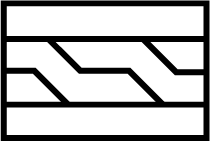

This machine represent a huge step ahead in the technology process of continuously transposed cables – CTC.

It operates according a new transposing principle that makes use of rollers for displacing the strips from one stack to the other, as illustrated in the figure on the left.

This innovative principle allows a very smooth, precise and fast bending of the strips without any damage to the enamel in the edges.

The machine is composed by two opposite heads that can be opened by moving each of them independently up and down either to fit different heights of the cable or to set different positions of the center line. The heads can also be opened to a max stroke to allow the total release of the cable for inspection.

The machine is powered by a servo-motor.

All the operations for setting different parameters are made on the control panel.

All the functional data are displayed on an colour screen.

Main data

Width of the strips: 3 – 13 mm

Thickness of the strips: 0.9 – 3.0 mm

Transposing pitch: 20 – 200 mm

Proteco produces different kind of taping units fit for various applications.

The taping units dedicated to the continuously transposed cables – CTC, belong to a new generation of products characterized by many innovative features:

• compact configuration, with 8 pads, 500 mm diameter, disposed in parallel-radial distribution

• very precise tensioning of the tapes performed by special electromagnetic brakes

• settings and adjustments of the taping parameters made on the control panel

• accurate monitoring of the emptying of the bobbins

• sophisticated kinematic with torque servo-motor for the best synchronization

• revolution speed of 500 rpm

• high safety level as per European standards

Proteco's catalogue includes many types of pullers with special features for various applications.

The puller used for the continuously transposed cables – CTC is a caterpillar type having the possibility of being rotated 90° around its longitudinal axis in order to clamp the CTC on top–bottom or left–right sides, this depending on which condition is more effective to avoid any slipping.

The cable is pressed and pulled by two reinforced wear-resistant belts. The clamping pressure is given by pneumatic pistons through groups of swinging rollers.

The CTC is kept aligned at both ends of the machine by two groups of adjustable rollers.

The machine is driven by servo motors.

All settings are made on a control panel placed on board. This panel includes also the valves for the air pressure regulation.

The pulling force for the available models ranges from 5 to 20 kN. The speed is up to 30 m/minute.

Take-ups made by Proteco are studied for various applications and cover a wide range of dimension and weight of bobbins. The proposed configuration is self-traversing, movable on rails, made of 2 columns holding the spindles, one idle and one motorized.

The spindles are mounted on carriages to be moved vertically on uprights by two independent motorized jacks. This allows to center the bobbins even in case of misalignment.

Upper stroke is limited by a switch; lower stroke is stopped when flanges touch the pavement.

Spindles are open and closed by a motor-jack through telescopic tubes.

The winding of the cable or wire can be controlled by pull or by speed, this depending on the cross- section.

The traversing motion is made by servo-motor.

The machine is equipped with a cable guide with vertical idle rolls and a dancer for the speed control.

Control panel

All the parameters are settable and displayed on a control panel with color screen.

Models

The machine is currently produced in three different models; any other size is available on request:

BTU800 for bobbins up to 800 mm of flange and 600 kg

BTU1000 for bobbins up to 1000 mm of flange and 2000 kg

BTU2000 for bobbins up to 2000 mm of flange and 8000 kg and more