The application of continuously transposed cable, CTC, has produced the effect of a revolution in the design of the transformers and has brought huge economical benefits to electric power industry.

Along with the increase of the unit capacity of the electric transformers, heavier and heavier low voltage (LV) currents have been involved, and therefore ever growing cross section area for the winding cables have requested. This area cannot just be obtained by connecting several CTC in parallel as the coil becomes intricate and some space get lost; for this reason CTC with more and more flat wires have been developed, so that from the original limit of 30 wires the demand today may exceed 80 wires.

However, the increase of the quantity of wires is far from representing an optimal solution to the need of transferring heavy currents, as new problems originated from very large sections; one of these problems is represented by the difficulty of keeping tight and straight the paper lapping layers when the radial height becomes very high, since the paper insulation become bulged after the winding, pressing and drying process and forms oil pockets on both sides of the cable; these pockets reduce the thermal exchange from the conductor to the coolant and throttle the effective section of the cooling ducts between two adjacent turns.

In order to ward off the above problem a first, important step has been the substitution of the paper wrapping with a plastic yarn binding or a taping net. Of course both these alternatives require a very good enamel insulation on the strips as no further protection can be given by the paper.

The new “Ventilated CTC”

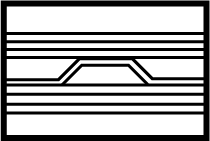

The further decisive improvement in the way of optimizing the CTC is represented by the new shape of the “Ventilated CTC”. In this cable one, or even more oil ducts crossing the transversal section of the cable along its whole length have been made. This remarkably increases the thermal exchanging surface therefore reducing at once temperature and electric resistance of the conductor.

All that above comes in the superiority of such cable compared with the traditional one as it allows, at the same time, to increase the efficiency of the transformer and to compact its size.

The new cable is shown in the figures aside. The slots-channels, acting as oil ducts, are made by bending, one by one on sequential predeterminated order, each strip of both CTC stacks in order to get a gap that separe two overlapped strips. Due to its geometry each wire exposes, in a turn, the same area to be licked by the oil, thus each wire gives identical contribution to the heat dissipation. The number of slots can also be chosen in order to optimize competing parameters like dimension and efficiency.

This new patented “Ventilated CTC” and its specific production process belong to Proteco. The typical line for the production of VCTC is presented in the lay-out illustrated below.

Costs of the VCTC

The industrialized process of production allows a cost of the VCTC not far from the one of the normal CTC. This can give it great technical and economical competitiveness, in comparison with handmade similar products obtained by the insertion of spacers.

Conclusion

The new ventilated CTC with its innovative characteristics can bring a considerable contribution to the engineers for the project of electrical transformers having higher efficiency and more compact design.

The production system enables to obtain excellent and constant quality.

The new proposed technology is therefore a very profitable investment in the CTC field, as it can be a milestone in its evolution.

The Stranding Cage is a modular structure made of disks connected through a central tube. Each disk holds the bobbins through pneumatic spindles on cradles shaped as open forks. The rotating structure is supported by idle wheels.

The forks are convergent to the center line to minimize the angular deviation of the strips.

The strips are tensioned by a block brake. The braking force is limited to a minimum, just enough to avoid the unrolling while stopping the line. This prevents from jerks that can deform the strips.

Each strip is guided inside tubes, that makes easier the threading of the machine.

The cage is rotated by an high torque electric motor with gear reducer, by using a very original configuration.

The emergency stop and the retention of the cage while loading are made by multiple pneumatic brakes.

Main data

The production of the ventilated CTC is made by the TH10 machine in a fully automatic and continuous process. This gives the product an excellent and constant quality.

This machine fulfills a preliminary bending of the flat wires in the direction normal to the transposition plane in order to get a shapes as shown in the pictures.

The TH10 machine sets the wires to be bent at predetermined time interval, according to a preselected recipe.

The bending operation is controlled by a sophisticated software.

The TH10 machine works in synchronization with the transposing machine.

Technical Data of the TH10 Operating Machine

Number of strips min. to max 43 to 63 strips

Thickness of a single strip min. to max 1.5 to 3.0 mm

Width of a single strip min. to max 8.0 to 12.0 mm

Tensile strength (e=0,2%) max. 220 N/mm2

Radial height of finished CTC up to 70 mm

Width of finished CTC up to 30 mm

Height of slot depending on the project

This machine represent a huge step ahead in the technology process of continuously transposed cables – CTC.

It operates according a new transposing principle that makes use of rollers for displacing the strips from one stack to the other, as illustrated in the figure on the left.

This innovative principle allows a very smooth, precise and fast bending of the strips without any damage to the enamel in the edges.

The machine is composed by two opposite heads that can be opened by moving each of them independently up and down either to fit different heights of the cable or to set different positions of the center line. The heads can also be opened to a max stroke to allow the total release of the cable for inspection.

The machine is powered by a servo-motor.

All the operations for setting different parameters are made on the control panel.

All the functional data are displayed on an colour screen.

Main data

Width of the strips: 3 – 13 mm

Thickness of the strips: 0.9 – 3.0 mm

Transposing pitch: 20 – 200 mm

Proteco produces different kind of taping units fit for various applications.

The taping units dedicated to the continuously transposed cables – CTC, belong to a new generation of products characterized by many innovative features:

• compact configuration, with 8 pads, 500 mm diameter, disposed in parallel-radial distribution

• very precise tensioning of the tapes performed by special electromagnetic brakes

• settings and adjustments of the taping parameters made on the control panel

• accurate monitoring of the emptying of the bobbins

• sophisticated kinematic with torque servo-motor for the best synchronization

• revolution speed of 500 rpm

• high safety level as per European standards

Proteco's catalogue includes many types of pullers with special features for various applications.

The puller used for the continuously transposed cables – CTC is a caterpillar type having the possibility of being rotated 90° around its longitudinal axis in order to clamp the CTC on top–bottom or left–right sides, this depending on which condition is more effective to avoid any slipping.

The cable is pressed and pulled by two reinforced wear-resistant belts. The clamping pressure is given by pneumatic pistons through groups of swinging rollers.

The CTC is kept aligned at both ends of the machine by two groups of adjustable rollers.

The machine is driven by servo motors.

All settings are made on a control panel placed on board. This panel includes also the valves for the air pressure regulation.

The pulling force for the available models ranges from 5 to 20 kN. The speed is up to 30 m/minute.

Take-ups made by Proteco are studied for various applications and cover a wide range of dimension and weight of bobbins. The proposed configuration is self-traversing, movable on rails, made of 2 columns holding the spindles, one idle and one motorized.

The spindles are mounted on carriages to be moved vertically on uprights by two independent motorized jacks. This allows to center the bobbins even in case of misalignment.

Upper stroke is limited by a switch; lower stroke is stopped when flanges touch the pavement.

Spindles are open and closed by a motor-jack through telescopic tubes.

The winding of the cable or wire can be controlled by pull or by speed, this depending on the cross- section.

The traversing motion is made by servo-motor.

The machine is equipped with a cable guide with vertical idle rolls and a dancer for the speed control.

Control panel

All the parameters are settable and displayed on a control panel with color screen.

Models

The machine is currently produced in three different models; any other size is available on request:

BTU800 for bobbins up to 800 mm of flange and 600 kg

BTU1000 for bobbins up to 1000 mm of flange and 2000 kg

BTU2000 for bobbins up to 2000 mm of flange and 8000 kg and more